Overview

Everything that the human race has built, the machinist has been a part of. Machinists have the critical role of creating the components necessary to construct everything around us, from the largest machine parts down to the smallest bolt. What used to take several days to construct now only takes a matter of hours due to the advancement of machining technology.

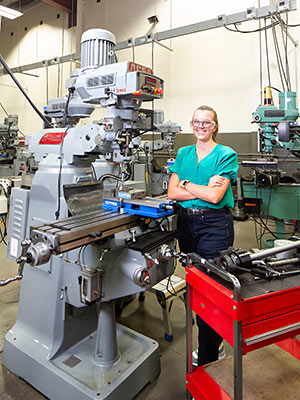

TMCC machining programs gives students the opportunity to receive hands-on training with industry professionals, as well as offers the most up-to-date equipment being used in the field today.

What Will I Study?

Along with learning the basics of CNC technology, students that decide to study machining will learn the fundamental concepts of industry print reading, and how to navigate technical drawing required by most machine shops. General safety and quality control classes are also included in the curriculum, to help you understand how to navigate the workspace, and to prepare them to work at industry standards.

CNC classes will be offered to aid you in the understanding of milling and lathing operations, as well as basic program formatting and machine setup. Upon completion of the Machining degree path, you will be able to interpret industry-grade technical prints, as well as be able to produce a variety of machine workpieces by using a variety of different codes and control functions.